ASTM A53 standard is the American Society for Testing and Materials. The standard covers a variety of pipe sizes and thicknesses and applies to piping systems used to transport gases, liquids and other fluids. ASTM A53 standard piping is commonly used in industrial and mechanical areas, as well as in the construction industry for water supply, heating and air conditioning systems.

According to ASTM A53 standard, pipes can be divided into two types: Type F and Type E. Type F is seamless pipe and type E is electric welded pipe. Both types of pipes require heat treatment to ensure that their mechanical properties and chemical composition meet standard requirements. In addition, the surface requirements of the pipe should comply with the provisions of the ASTM A530/A530M standard to ensure its appearance quality.

The chemical composition requirements of ASTM A53 standard pipes are as follows: carbon content does not exceed 0.30%, manganese content does not exceed 1.20%, phosphorus content does not exceed 0.05%, sulfur content does not exceed 0.045%, chromium content does not exceed 0.40%, and nickel content does not exceed 0.40 %, the copper content does not exceed 0.40%. These chemical composition restrictions ensure the strength, toughness and corrosion resistance of the pipeline.

In terms of mechanical properties, ASTM A53 standard requires that the tensile strength and yield strength of pipes are not less than 330MPa and 205MPa respectively. In addition, the elongation rate of the pipe also has certain requirements to ensure that it is not prone to breakage or deformation during use.

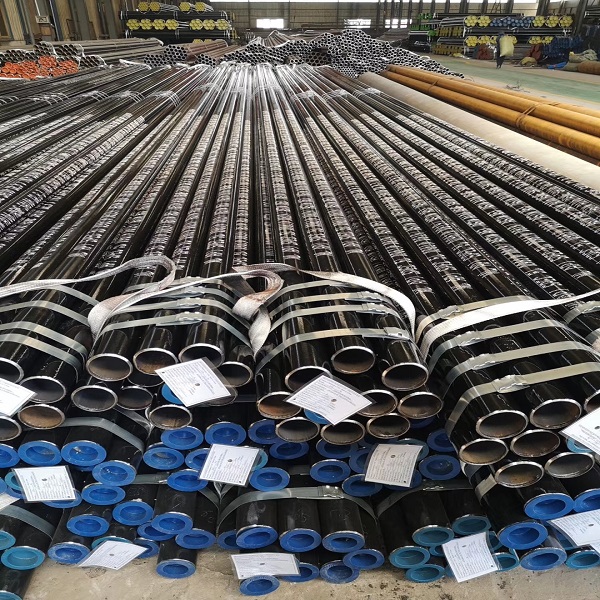

In addition to chemical composition and mechanical properties, the ASTM A53 standard also provides detailed regulations on the size and appearance quality of pipes. Pipe sizes range from 1/8 inch to 26 inches, with a variety of wall thickness options. The appearance quality of the pipeline requires a smooth surface without obvious oxidation, cracks and defects to ensure that it will not leak or be damaged during installation and use.

In general, the ASTM A53 standard is an important standard for carbon steel pipes. It covers the requirements for the chemical composition, mechanical properties, dimensions and appearance quality of the pipes. Pipes produced according to this standard can ensure stable quality and reliable performance, and are suitable for piping systems in various industrial and construction fields. The formulation and implementation of ASTM A53 standards are of great significance for ensuring the safe operation of pipelines and promoting the quality of project construction.

Post time: Apr-11-2024