0102030405

EN10216 Seamless Steel Pipe

2024-04-09 15:15:50

EN10216 seamless steel pipe-EN10216 alloy steel pipe

"High Temperature Characteristics of Seamless Steel Pipes for Pressure Use of Non-Alloy and Alloy Steel Pipes"

Product grades: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2, P195GH, P235GH, P265GH, 13CrMo4-5, 10CrMo9-10

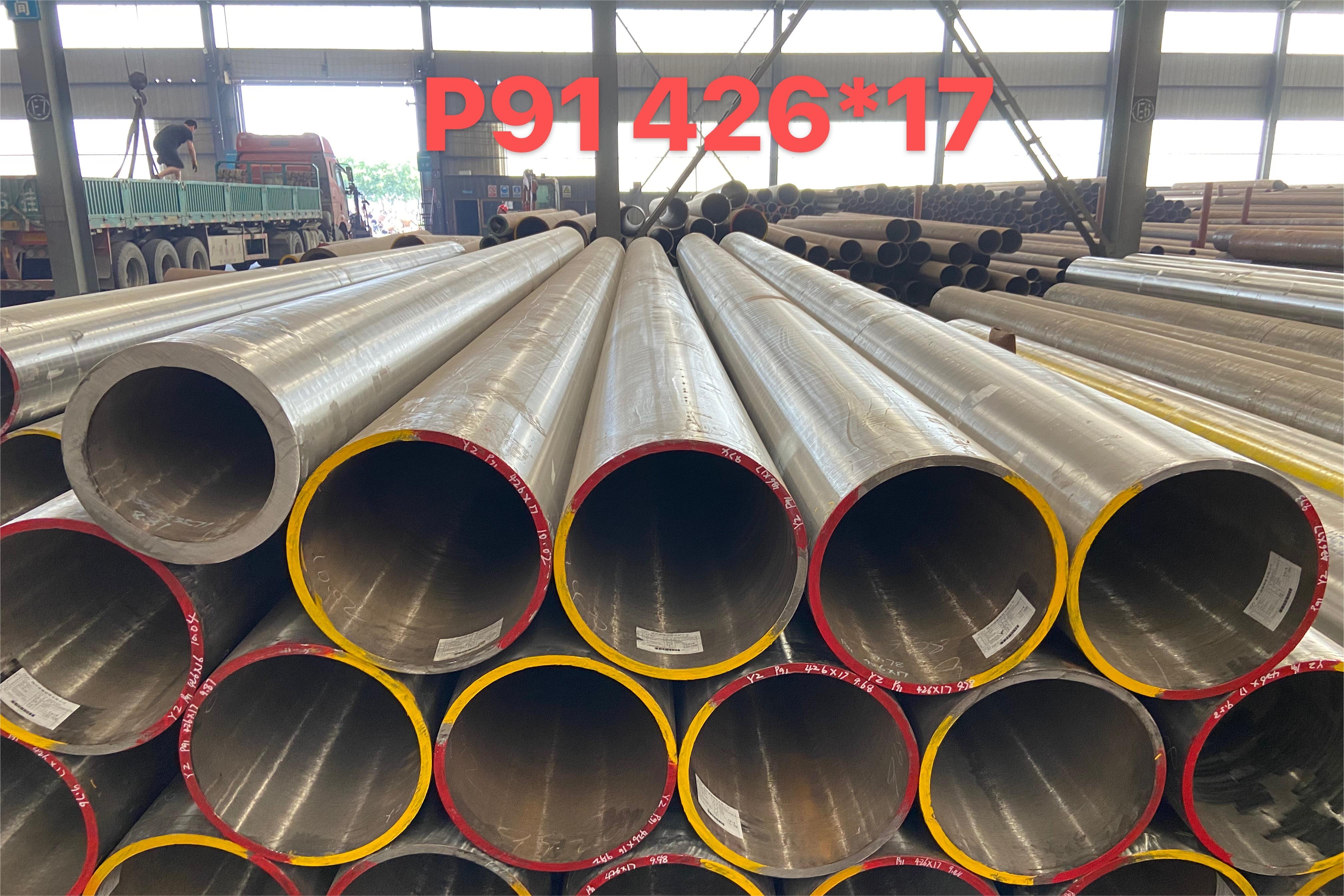

Product specifications: outer diameter Φ21.3mm~762mm, wall thickness 2.0~130mm

Production method: hot rolling, cold drawing, thermal expansion, delivery status: heat treatment

The product should comply with the requirements of TSGD7002-2006 "Type Test Rules for Pressure Pipe Components".

EN 10216-2 is a European standard that specifies the technical delivery conditions for seamless steel pipes for pressure applications. This standard covers steel pipe for a variety of uses, including high and low temperature applications.

Purpose: Suitable for manufacturing pressure-bearing pipes, containers, equipment, pipe fittings and steel structures

P265TR2 is a steel pipe material with excellent mechanical properties. Its yield strength is 265MPa, tensile strength is 410-530MPa, and elongation is 23%. These performance indicators make P265TR2 widely used in industrial fields. P265TR2 steel pipe material is commonly used in piping systems carrying high-pressure gases or liquids. Due to its reliable mechanical properties, P265TR2 steel pipe can maintain good stability and safety in high-pressure environments. In addition, P265TR2 steel pipe also has good corrosion resistance and wear resistance, and can be used for a long time in harsh environments. In short, P265TR2 steel pipe is an excellent pipe material with excellent mechanical properties and is widely used in various high-pressure pipeline systems.

P265TR2 is a steel pipe material used for high-pressure gas transportation. Its inspection methods mainly include the following aspects: 1. Appearance inspection: Check whether there are cracks, scratches, dents and other defects on the surface of the pipe, and check the length, diameter, wall, etc. Whether the thickness complies with regulations. 2. Dimensional inspection: Use measuring tools to accurately measure the outer diameter, wall thickness, length, etc. of the pipe to ensure that it meets the specified standards. 3. Chemical composition analysis: Sampling the internal materials of the pipe and using chemical analysis instruments to analyze its composition to ensure that its chemical composition meets the specified standards. 4. Mechanical property testing: Conduct tensile, bending, impact and other mechanical property tests on the pipe to ensure that its strength, toughness and other properties meet the specified standards. 5. Non-destructive testing: Use non-destructive testing equipment to conduct ultrasonic, radioactive, magnetic particle and other non-destructive testing on the pipe to ensure that there are no cracks, pores and other defects inside. Through the above testing methods, it can be ensured that the quality of P265TR2 steel pipe meets the standards and ensures its safe and reliable use in the field of high-pressure gas transportation.